Pipes rehabilitation

Pipeline rehabilitation is the restoration of a damaged part of a tube without massive ground works and lengthy concomitant road closure

"Two thirds of the country's electricity supply networks, 57% of thermal communications and almost half of the water supply networks are worn out. These figures speak for themselves"

from the message of the President of Kazakhstan Kassym-Jomart Tokayev

From the message of the President of the Republic of Kazakhstan Kassym-Jomart Tokayev, it becomes obvious that many engineering networks and highways of life support systems are severely worn out

The majority of communications were installed back in Soviet times with the expectation of a planned replacement or complete reconstruction of the area. Therefore, the standard service life of the pipes was limited

In many cases, it has already expired, but worn-out and often rusted pipe systems continue to work, which, of course, sooner or later leads to destruction, leaks, blockages and other problems. Repairing such pipes in the classical way with digging a trench is long, expensive and not always possible, and sanitation becomes a way out of the situation

The sanation of pipelines allows you to solve the following tasks

Restore pipes after corrosion

Restore pipes after partial wear due to corrosion

Replace worn-out sections of the pipeline

Partially replace worn-out sections of the pipeline without complete dismantling and large-scale excavation and related works

Replace the destroyed sections of the pipeline

Completely replace sections of pipe that have been destroyed to such an extent that their restoration is no longer possible

Advantages of sanitation

Pipes sanitation

We restore pipes with little time and resources, without carrying out large-scale ground works

High porosity, low resistance to water hammers, as well as natural exposure to corrosion are potential pipe problems due to the characteristics of the materials

Sanation technologies make it possible to compensate for the listed flaws

An important advantage of this technology is the possibility of its application for the restoration of pipes made of various materials

Steel pipes

Cast iron pipes

Reinforced concrete pipes

Polymer pipes

Advantages

In addition to the small mass of polymer pipes, a large assortment of their standard sizes, durability and the ability to work in the cold season, trench-free pipeline sanitation has other advantages

Traffic

The traffic flow does not stop on the road laid over the damaged section of the sanitized engineering and technical highway

01

Minimal ground works

Minimal need for earthworks, which significantly reduces the cost of special equipment (excavators, dump trucks, etc.)

02

Simplified projects and estimates

Simplified drafting of technical projects and estimates, because all actions are carried out on a limited section of engineering communications

03

Quality and speed of movement of the medium

The quality and speed of movement of the medium transported by the pipeline increases, thanks to the smooth inner surface of the polymer liner

04

Less need for special equipment

Access of special equipment is not always required, which allows the method to be applied on limited areas and attract a minimum of employees

05

Access to the inner surface

Access to the inner surface of the sections at turns, bends, branches of the main pipeline is provided

06

Increased service life

The predicted service life of pipes after sanitation is up to 50 years, depending on the primary condition of the pipe

07

The repair time is reduced by 3-5 times

Reduces the time required for repair by 3-5 times compared to an open gasket

08

Bypassing adjacent communications

Does not affect adjacent communications and highways laid nearby

09

Work without stopping drains

There is an opportunity to carry out work without stopping drains

10

Leave an application now to obtain a consultation

We know how to restore pipes without carrying out large-scale land works, with minimal costs to extend the service life and quality

After the application, our specialists will consult you and make a proposal for your request

Areas of application

Water supply and sewerage networks

Domestic water and sewer networks are worn out most seriously, while their operation is carried out in an intensive mode. It is extremely inconvenient to repair them in the usual trench way, unlike sanitation method

Drainage and stormwater systems

Reconstruction of drainage and stormwater systems on adjacent urban and suburban areas, public and industrial buildings and structures is also carried out by means of trench-free sanitation

General and technological engineering networks

The method has been mastered by industrial enterprises - it is used for the reconstruction of general and technological engineering networks laid on their territory

Engineering, technical and utility infrastructure

Also, the sanation is suitable for the reconstruction of urban engineering and utility infrastructure: pipes of fountains, common areas of communications, etc.

Features of pipeline sanitation

The sanation of the pipeline requires a preliminary examination of the damaged highway and a recovery plan

The work of most utilities, except for sewer systems, should be suspended for a while

When ordering rehabilitation works, it is necessary to take into account the specifics of their implementation

Technical features

The restoration of pipes depends on the diameter and type of pipe, also during the rehabilitation, the distance between the wells should not exceed 500 m

Title

Diameter

Pressure system

150 - 1500 mm

Pressure-free system

up to 3500 mm

Polymer pipes

100 - 2800 mm

Stages of pipeline rehabilitation

Condition assessment

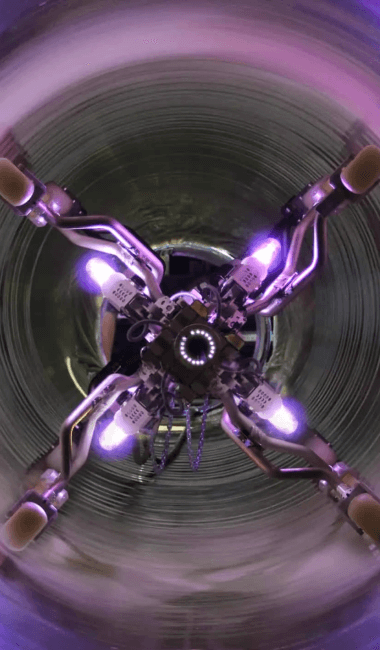

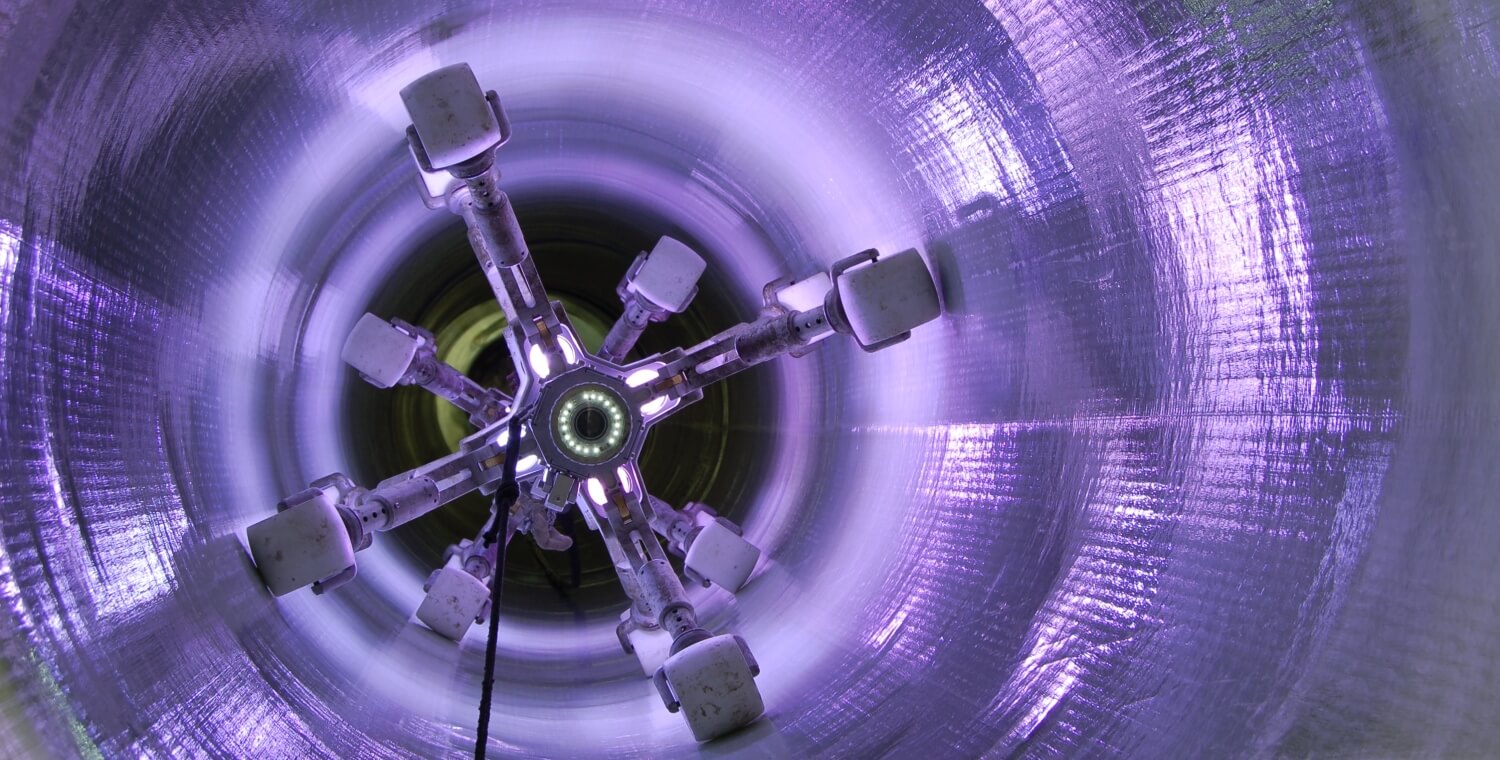

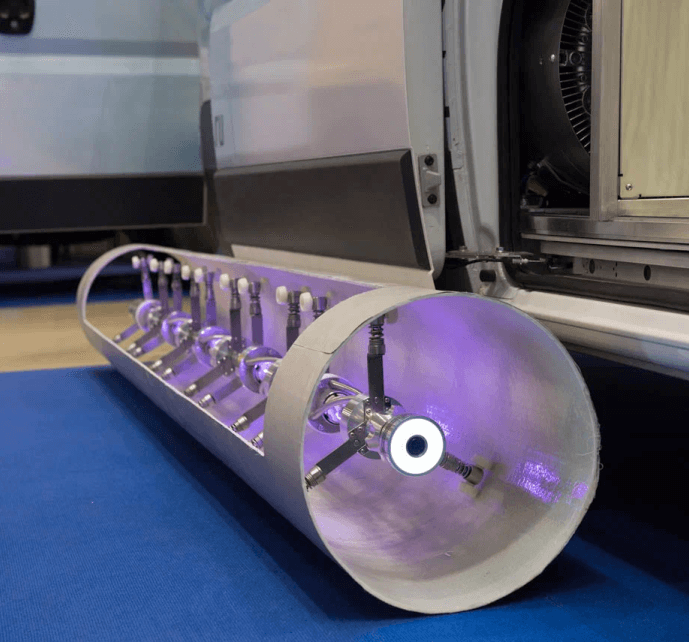

First, a self-propelled robot with a camera and a lamp is launched to assess the condition of the inner surface of the pipe to identify problem areas

01

Pipeline cleaning

After that, sand, calcium, carbonates and rust are cleaned by mechanical and hydraulic methods, while thinning of the walls is possible

02

Measure the diameter of the lumen

Upon completion of cleaning, a second revision is carried out and the diameter of the lumen is measured

03

Pipe broaching and installation

Next, a new pipe is inserted into the existing one, which is filled with water or air, heated for polymerization and connected to existing communications

04

Control inspection

After carrying out all the work, a robot is again launched into the repaired section for a control inspection of the pipe

05

International experience in the implementation of pipe sanitation

The international company YAROV GROUP develops the application of pipeline sanitation using world experience and advanced technologies

In Kazakhstan, the YAROV GROUP company is represented by the enterprise "Tore-Chingizid L.T.D.". The key principle of synergy is the introduction of international experience in the implementation of pipeline rehabilitation to achieve the most effective long-term result

All services provided comply with the required standards and are carried out on the basis of permits and certificates of conformity. We use exclusively modern and advanced equipment and technologies, all our employees have extensive experience and regularly undergo professional development

This approach allows us to implement the rehabilitation of pipelines at a high level in compliance with deadlines and agreements

Leave an application now to get a consultation and an estimate for your project